Every day is a safety day at Reka Cables

Every day is a safety day at Reka Cables

In cable manufacturing, safety at work requires a systematic approach. Following safety practices reduces the risk of accidents and improves the safety and well-being of workers.

Safety at work is a broad concept and in the cable industry it includes risk assessment, use of personal protective equipment, safety of machinery and equipment, chemical safety, electrical safety, ergonomics, training and instruction of workers, emergency management and compliance with legislation and standards.

“At Reka Cables, safety is our number 1 obligation and we are all responsible for it every day,” says Emma Lehtonen, Safety Manager at Reka Cables.

Safety objectives and implementation

Reka Cables has a zero target for serious accidents. The company develops its activities in cooperation with staff, occupational health, authorities and experts.

“We have a safety programme in place, including Golden Rules and SUSA cards for employees to report their safety observations. Winningtemp – an AI tool to help employees express their feelings,” says Lehtonen.

Safety Day is also celebrated at Reka’s Finnish sites.

“Although every day is a Safety Day, the purpose of the designated Safety Day is to raise awareness, stimulate ideas and discuss safety in a positive way,” Lehtonen reminds.

Safety Day 2024 at Reka Cables

Safety Day 2024 at the Keuruu and Riihimäki production sites focused in particular on hand safety and cable reel handling.

“Everyone was asked to think for a moment about what they need or want to use their hands for. Although hands are the most important tool for almost all of us in our daily work, each of us also needs our hands outside the workplace fence. We reminded ourselves of the requirements for hand protection and coil handling in line with our golden rules and went through our range of hand protection and coil handling tools and equipment,” says Emma Lehtonen, Safety Manager.

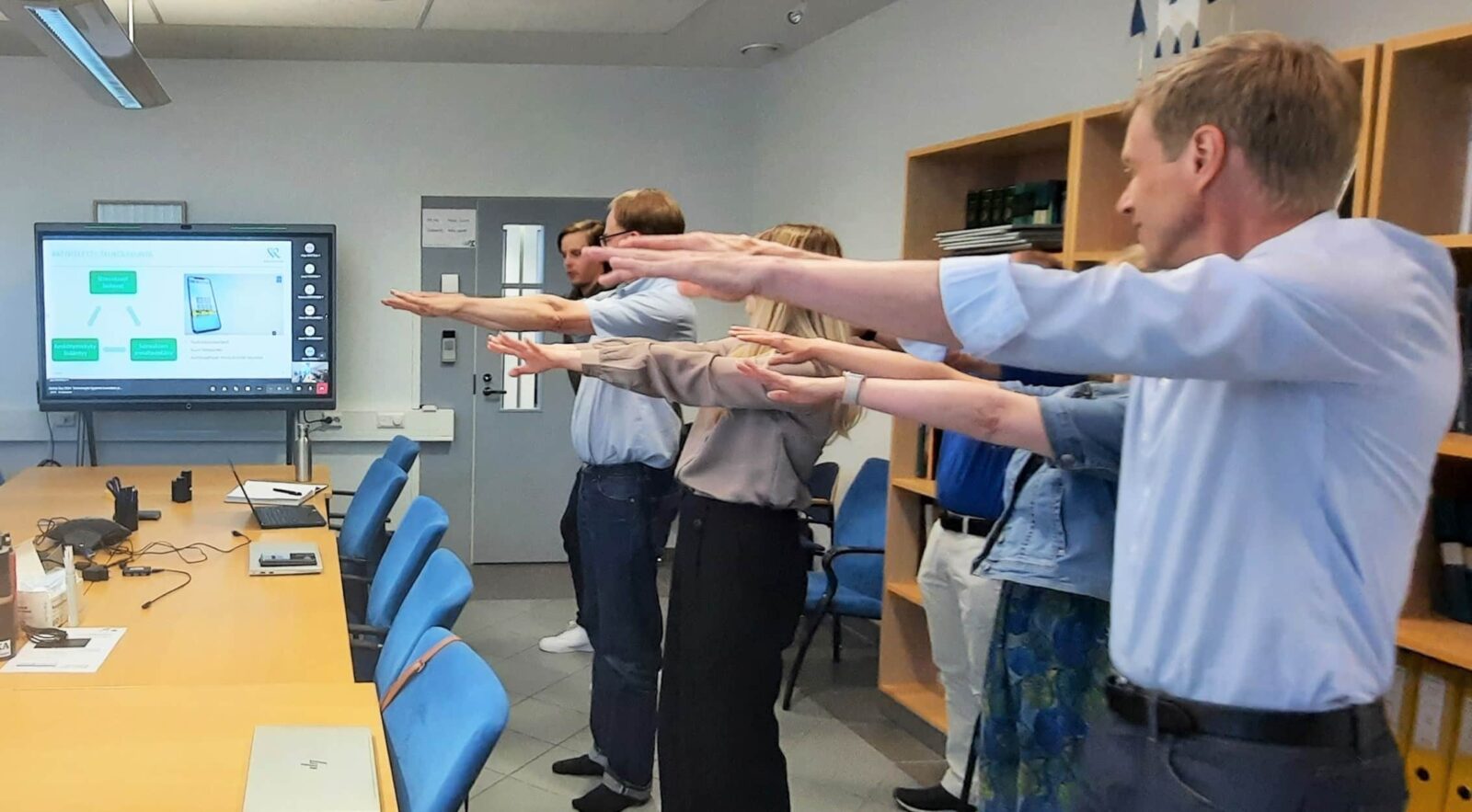

At head office, the theme was physical stress in office work. In addition to a lecture by an occupational health physiotherapist, practical exercises were carried out to maintain work capacity.

In addition to the activities in the production plants and at headquarters, all staff had the opportunity to participate in an online quiz on machinery and hand safety, with prizes drawn for all participants.